Lift Controller

- General

- Details

- Brochure

- Technical Documents

- Certificates

- Mikronik® S-Hi/P is a lift controller which has CAN-Bus based serial communication with car.

- Mikronik® S-Hi/P has designed to serve for high rise lifts.

- Mikronik® S-Hi/P is designed for quick and fault free connections in the control panel.

- For Gearless, VVVF, two speed and hydraulic lifts.

- Maximum number of stops that can be serviced up to 16 and operation up to 1,60 m/s.

- Can be serviced simplex, duplex and triplex.

- Fireman operation activated via fireman switch in compliance with EN81-72

- Certification by the notified body Liftinstituut on the basis of the Lifts Directive 95/16/EC, EN 81-1 and EN 81-2

Tasks of H/CPU Card

- H/CPU card is placed in control board and is the main card of lift control system. All of the isolated signals coming from lift shaft, doors, cabinet and floors are transferred to H/CPU card and executes working of the lift pursuant to lift working principles according to program algorithm.

Tasks of H/CAB Card

- H/CAB card is placed in inspection box. This is the card to which input and outputs like calls in the cabinet, cabinet lamp, automatic door output are connected. It communicates with H/CPU card placed in control board via CAN Bus.

Tasks of H/PIO Card

- Additional card for increase the number of stops.

- DSB Card

- Re-levelling with open doors in harmony with EN81-2 in hydraulic lifts.

- Detachable Hand Terminal

- Detachable hand terminal for the user accessing the menu via the buttons and the graphics LCD display

H/BDR Card - Optional card for independent control of the second door.

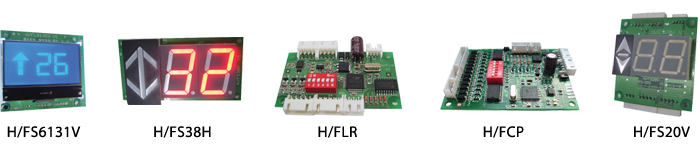

Floor cards for serial communication with landings

- H/FCP: Without display on the floor card (existed displays in the button panel can be use).

- H/FS20: 7-Segment display on the floor card

- H/FL6131: LCD display on the floor card

- H/FLR: Floor card for access to the call buttons, direction arrows, gong and out of service signals (In case of without display in the button panel).

- H/FAD Card

- Various types of control can be selected by the user from the menu

– Non-collective universal control upto 32 stops (S24)

– Single-button downcollective upto 32 stops (1KSA)

– Single-button up- and downcollective upto 32 stops (1KSL)

– Double-button up- and downcollective (selective-collective) upto - 32 stops (1KS)

- Dublex and triplex group operation for all control types

- Advanced door opening

- Automatic re-levelling

- Position and re-levelling information in hydraulic lifts with 2 monostable magnetic switches and strip magnets

- Parameters adjustable by user on detachable hand terminal for populer hydraulic units

– Brand and type of the hydraulic unit

– Starting method

– Star starting time

– Motor stopping and valve de-energizing delays - Cost reduction and higher security level of system settings thanks to the detachable hand terminal

- Indication of lift status and detected errors on the graphics LCD on the detachable hand terminal

- The built-in real time clock with battery back-up enables registration of detected errors with time and date stamp helping to trace back the occurred faults.

- Standard serial communication with the car via the reliable CAN Bus helps to save the number of traveling cables required

- User programmable short-circuit protected gray code or binary outputs for landings via optional PIO8 card

- User programmable short-circuit protected outputs on the cards H/CPU and H/CAB

- Motor overheat monitoring function (P1, P2) in compliance with EN81

- Earthquake function (806) delivering the passengers to the next possible stop

- Fire emergency operation via fire alarm input with user adjustable evacuation stop in compliance with EN81-73 (816)

- Fireman operation activated via fireman switch in compliance with EN81-72 (813)

- User selectable position information methods:

– Using Gray-coded bi-stable magnetic switches (M0, M1, M2…) possible upto 16 stops.

– Mikopulse magnetic switch instead of Gray-code switches

– Shaft copying with encoder - Independent control of the second door via the optional card H/BDR

- Remote monitoring on a PC

Please click to see technical documents.